Product Center

Meet your test standards such as ISO, ASTM, EN,DIN, JIS, IEC, GB,GJB,MLT, etc.

-

Environment Test Machine

-

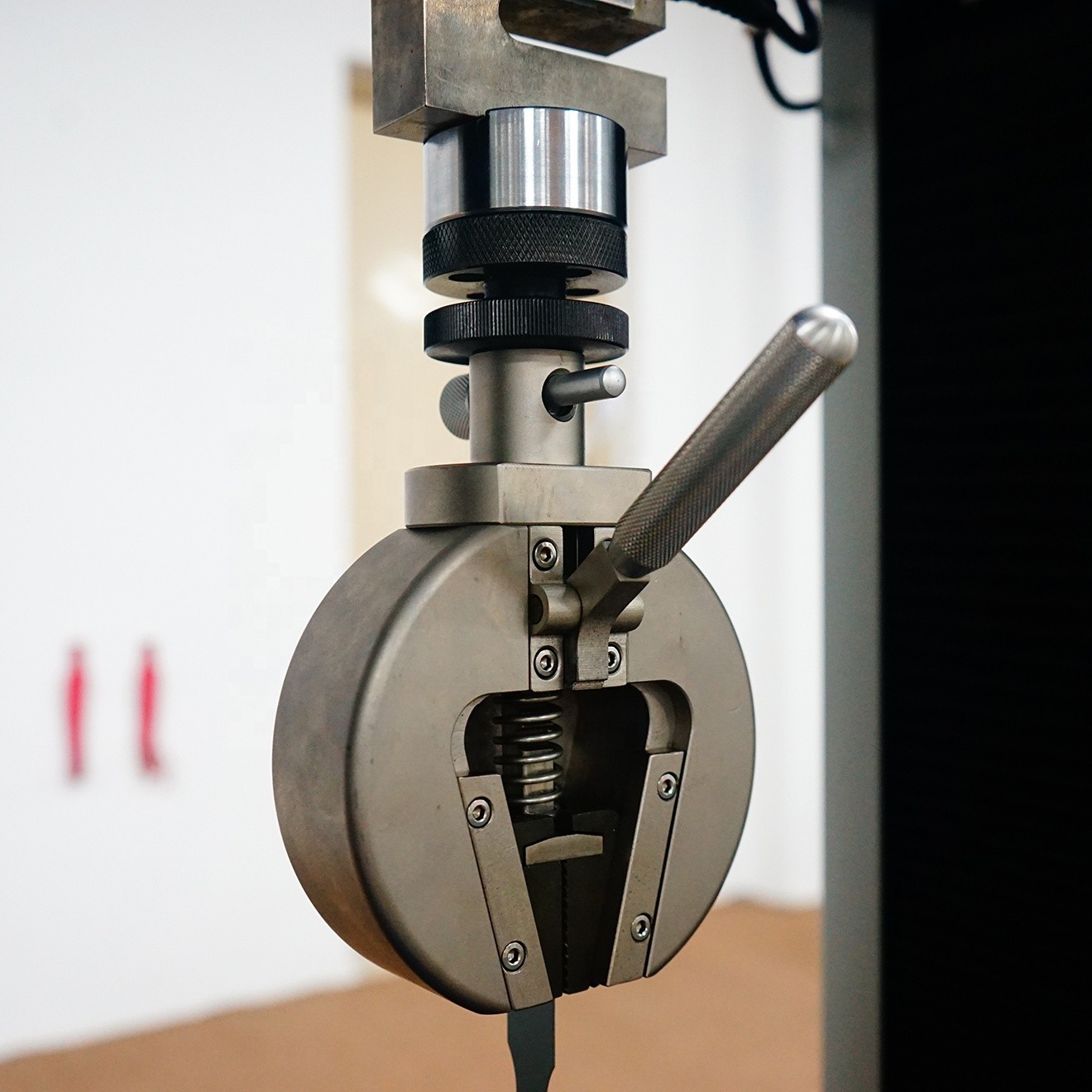

Universal Test Machine

-

Battery Test Machine

-

Vibration & Shock Test Machine

Let us wow you!Have a unique application? Let’s start talking about yourenvironmental test application. We can help configure a standardchamber or design a custom system.

REQUST A QUOTE- 20+20 years of experience in research, production and marketing

- 6w+2 large manufacturing bases 60,000 square meter

- 150+150 highly educated engineer with over 10 years experience

- 102+2 national invention patents More than 100 utility model patents

HUDA TECHNOLOGY

Why Choose Us?

HUDA is a sub-brand of the Quality Test Service Group, a national high-tech enterprise engaged in the design, development, production, sales, calibration and after-sales service of reliable environmental testing equipment. With a total area of 60,000 square meters and 2 production plants, the group has provided quality services to more than 28,000 customers worldwide.

Service Flow

High-end testing equipment research, production and marketing integration

- 1Customer Requirements

- 2R&D Design

- 3Design Finalization

- 4Customer Finalization

- 5Material / Production

- 9On-site Installation and Training

- 8Finished Product Shipment

- 7Finished Product Inspection

- 6Installation and Commission

- 1Customer Requirements

- 2R&D Design

- 3Design Finalization

- 4Customer Finalization

- 5Material / Production

- 6Installation and Commission

- 7Finished Product Inspection

- 8Finished Product Shipment

- 9On-site Installation and Training

”

Customer Testimonials

The trusted choice of 28000+ customers

News & Event

Witness every progress of HUDA and testing equipment industry