Specifications

| Model | HUD-H210 |

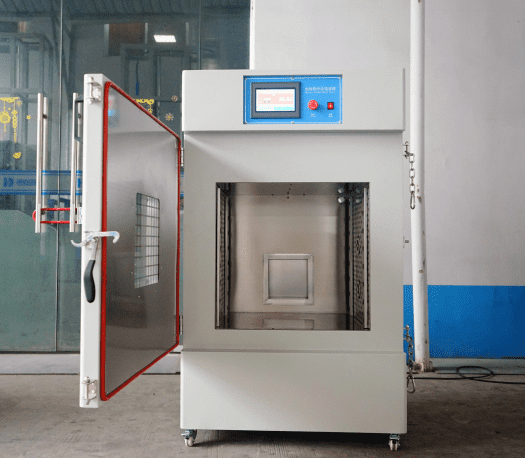

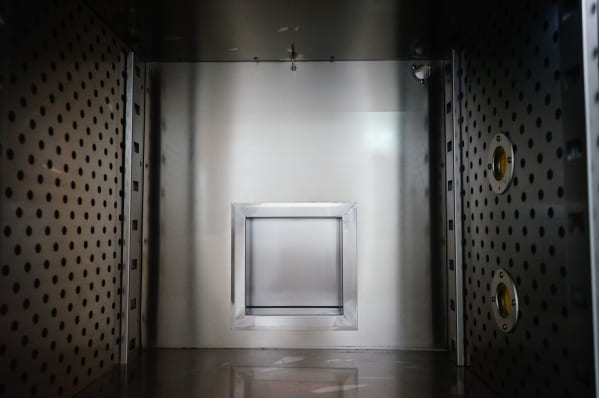

1. Inner box size | 400x400x400mm (width x depth x height); |

2. Dimensions | 800x700x1310mm (width x depth x height); |

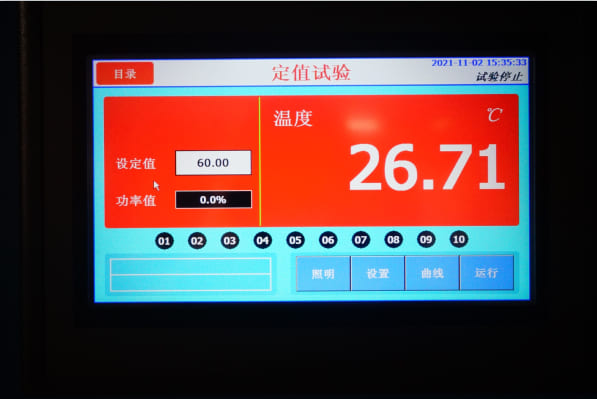

3. Temperature range | RT+10~200℃; |

4. Temperature display accuracy | 0.1℃; |

5. Temperature stability | ±1.0℃; |

6. Temperature uniformity | ±2℃; |

7. Heating time | (5±1)℃/min; |

8. Internal material | SUS304 stainless steel plate, thickness 1.2mm; |

9. External material | 1.5mm thick cold-rolled steel plate with paint treatment; |

10. Box door | a single door opens to the left, and an explosion-proof chain is installed on the side of the box door; |

12. Control method | push-button control; |

13. Pressure relief door size | 200x200mm; |

14. Smoke exhaust pipe | diameter φ100mm, located at the back of the box; |

15. Observation window | Two-layer tempered glass with a size of 250x250mm, equipped with stainless steel mesh; |

16. Temperature control meter | Programmable temperature controller, which can control the total heating time, which is different from ordinary temperature control meters. |

17. Power supply | 1∮, 220V, 20A |

Features

TEST STANDARD

UN 38.3 "United Nations Manual of Transport Tests and Standards for Dangerous Goods"

IEC 62133 "Battery (pack) composed of batteries and safety requirements for portable equipment"

UL 1642:2012 "Lithium Battery Standard"

GB/T 31485-2015 "Safety requirements and test methods for power batteries for electric vehicles"

GB/T 31241-2014 "Safety requirements for lithium-ion batteries and battery packs for portable electronic products"

FEATURES

Over-temperature protection system: When the temperature is out of control and exceeds the set temperature of the over-temperature protector, the heating and power supply will be automatically stopped to protect the safety of products and machines;

Circuit protection system: grounding protection, fast insurance, overload protection, circuit breaker, etc.

Safety device protection system: pressure relief device (explosion-proof pressure relief port); door protection device (explosion-proof chain)

PT100 thermal resistance temperature sensor: high precision, fast sensing temperature, high temperature resistance

Corrosion resistance and high temperature resistance: inner chamber adopts 304# mirror panel;the outer chamber is made of cold-rolled steel plate, sprayed with paint

Easy to move with casters

Can be customized in size