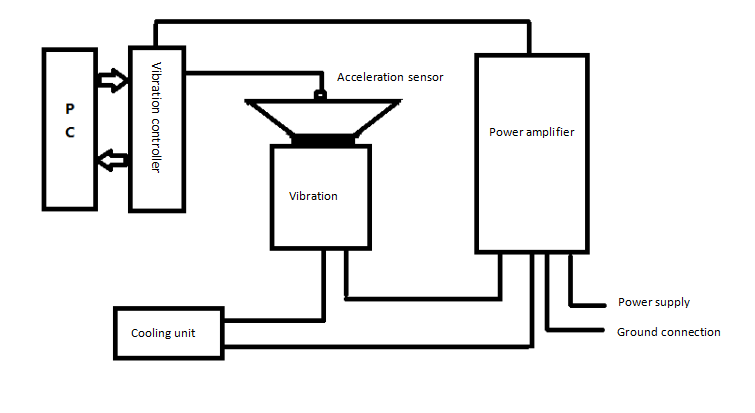

System Diagram

Specifications

Features

(1) vibration table

A. High reliability of the system, especially suitable for long working hours.

B. Air spring load support.

C. Solid ear-shaft design with bearing guide.

D. Built in airbag or rubber vibration isolation device to reduce ground dynamic vibration.

E. The rocker arm suspension system and roller guide have high anti-bias torque.

F. Double magnetic circuit structure: compared with the single magnetic circuit, the magnetic field intensity, the volume of the platform is small, and the magnetic leakage is small.

G.Fully sealed structure, strong adaptability to the environment, avoid dampness corrosion, reduce high and low potential difference, effectively solve the problem of electrochemical corrosion

H.Design of moving coil structure: the mass and stiffness of each part of moving ring skeleton are calculated and reasonably distributed by using long accumulated design experience, so that the mass and stiffness of structure are fully utilized. In addition, the design of the face force transfer angle plate is innovated, and the stiffness of the moving ring frame table is improved significantly.

I.Driving coil conductive lead: the elastic suspension of the coil is composed of two groups of Beryllium bronze U-type laminated spring assemblies, which are installed in the upper part of the platform. Each group of U-shaped springs is composed of dozens of thin Beryllium bronze U-shaped spring sheets. Because of its high fatigue resistance, long working life, we are used as the elastic suspension of the moving ring, and because of its good conductivity, we are used as the current lead of the drive coil.

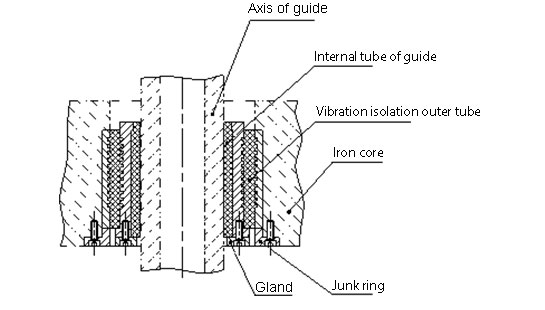

J.Guide structure: the upper direction of moving parts is guided by compound roller, and the lower guiding device is made of self-developed high wear-resistant, self-aligning linear sliding bearing structure, and the guiding inner cylinder is finely machined with composite material with high wear resistance and self-lubrication. The vibration isolation outer tube assembly is used to provide the adjustment amount in the axis alignment.

K.

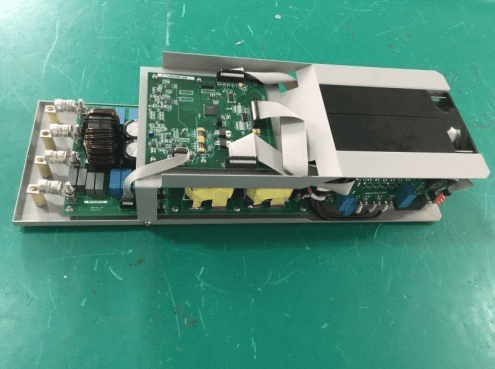

(2) Power amplifier

A. 8~1000kVA.

B.DSP +FPGA architecture, with advanced digital control strategy.

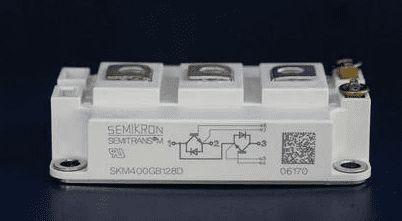

C. The new power device using IGBT has high voltage, high power, high reliability, high input impedance, low gate drive power, simple driving circuit, fast switching speed, short closing time, large safe working area and not easily damaged in use. Compared with MOSFET, the current density of IGBT is 10 times that of MOSFET, the turn-on resistance is less than 10% of RDS (on) with MOSFET, and the saturation voltage

D. Adaptive center zero adjustment function.

E. E.Switching frequency up to 150kHz.

F. F.Wide frequency range (DC~8kHz).

G.Automatic current sharing strategy, parallel current imbalance less than 1%

H.3 times instantaneous current output, suitable for random, impact test.

I.High conversion efficiency, > 95%.

J.Excellent air-cooled design

K.Complete interlock protection functions: output over-voltage, output over-current, amplifier over-temperature, vibration table over-displacement, horizontal slide platform over-displacement, cooling system failure, output power under-voltage, power amplifier unit failure, excitation power failure, Failure of three-phase power supply etc.

K.100% power module tested for aging

(3) vibration control system

A. The first domestic production, with the international mainstream level of digital vibration control instrument, with many years of technology accumulation and perfect control technology, the market has installed more than 5000 units;

B.The closed-loop control is realized by DSP processor and PC is independent of the control loop, which ensures the real time and high efficiency of the control system.

C. Low noise Design process for 24-bit ADC and DAC,32 floating-Point DSP, with dynamic range larger than 120dB.

D.The dynamic range of stochastic control is larger than that of 90dB.

E.Sinusoidal controllable frequency range to 10, 000 Hz, random controllable frequency range to 20000Hz.

F.The number of spectral lines in random test can be up to 6400 lines.

G.G.13 types of control functions to help you easily complete all kinds of vibration test.

H.Sinusoidal plus random support wide-band external sine.

I.As many as 20 security checks and interlocking settings to maximize the safety of testers, test pieces and shaking table equipment.

J.PC software is based on Windows operating system, graphical interface, rich window, cursor type, font, color and so on can be easily modified.

K.Professional test reports can be generated automatically after the test is completed in a format that supports Word,PDF and direct printing.