Features

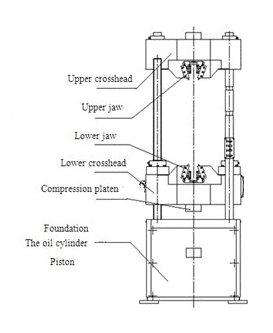

STRUCTURE

Large diameter columns and rugged components for durable frame:Dual power mechanism servo motor gear pump.Dual motors. Dual oil pumps, gear oil pump for boosting. The separate oil supply of the clamp and the oil cylinder is stable and reliable. (The traditional three-phase asynchronous motor supplies oil for the clamp, and the servo motor supplies oil for the oil cylinder. It is ultra-quiet and the noise is less than 70 decibels. The loading is more stable and faster. The sample clamping is more reliable and durable.)

Independent external controller: The addition of an independent external manual control unit provides a new solution for the measurement, control and operation of the testing machine. USB data transmission fully supports notebook computers, tablet computers, and desktop computers; it is an important part of leading the development of testing machine technology.

Multifunctional handheld controller: It can control the rise and fall of the moving beam and the oil cylinder, the clamping and unclamping of the jaws, and the emergency stop function of the oil pump, which is more convenient to use the sample clamping.

Operation monitoring system: It has the function of phase sequence, phase loss self-check indication, electrical overcurrent, overload and other protection functions, so that the equipment operation is safe and reliable.

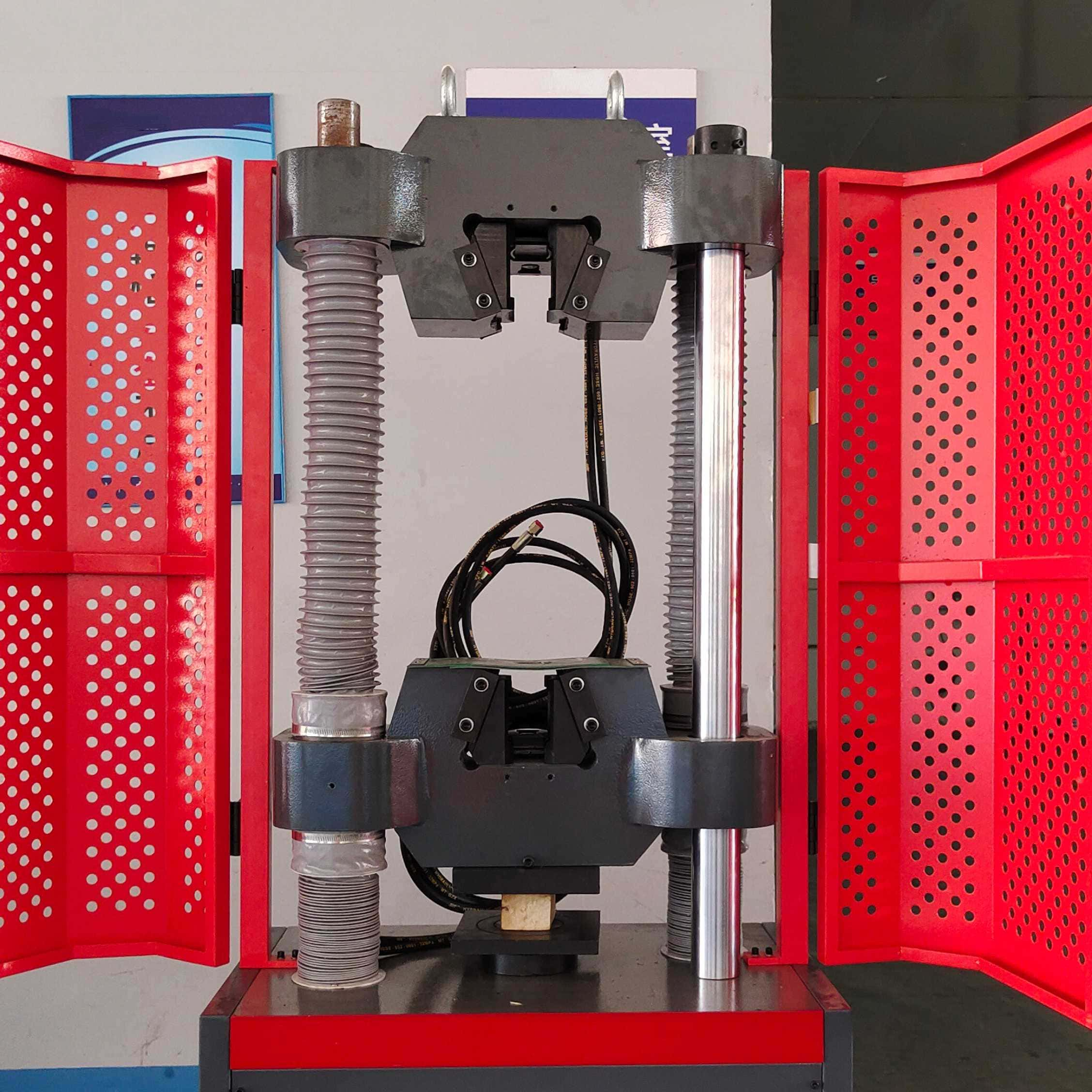

Elastic damping mechanism: The lower part of the lead screw is equipped with an elastic damping mechanism Effectively reducing the impact caused by the fracture of the sample and reducing the noise.

Flexible dust cover: Prevent foreign objects from entering, to increase the durability of the lead screw and transmission mechanism, and to improve the aesthetics of the whole machine

Safety shield: Three-sided cold-rolled steel plate punching safety shield to prevent foreign objects from flying out during the test. It improves the protection level and facilitates real-time observation by operators, effectively ensuring the personal safety of the experimenter.

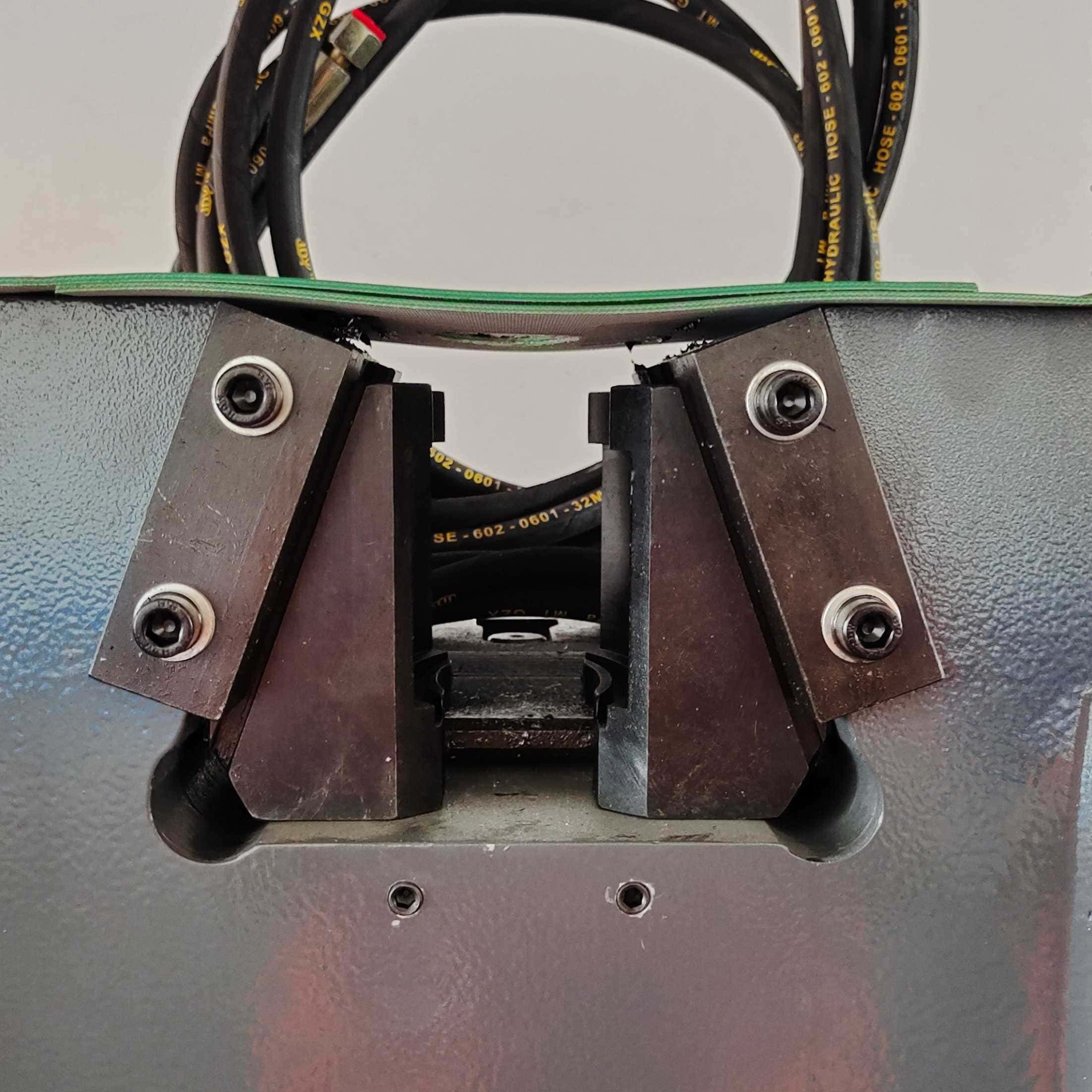

Cartridge valve type differential pressure follow-up technology: The servo pump station adopts the cartridge valve type differential pressure follow-up technology. It is energy-saving, environmentally friendly, safe and reliable, and reduces the heating of the system; at the same time, the clamping force increases with the increase of the test force, and the sample is firmly clamped.

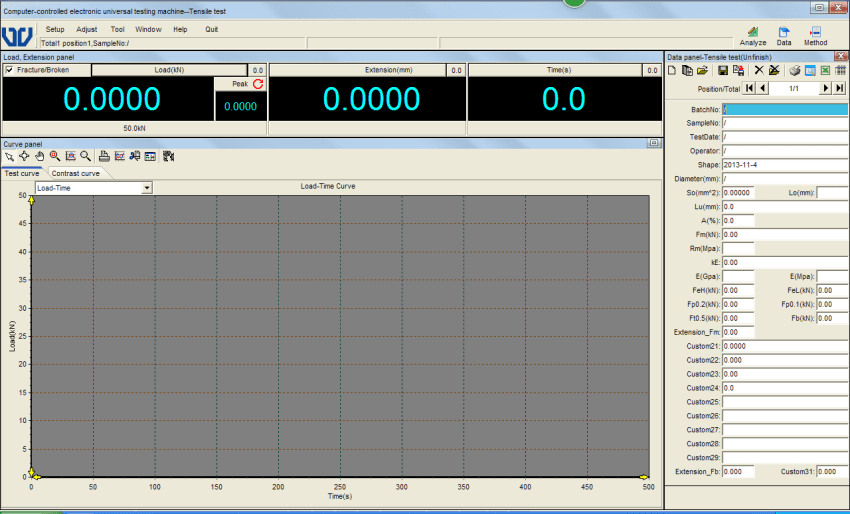

SOFTWARE

Data Acquisition:provides data acquisition and management for compression, tensile and splitting tensile test throughout the test execution. Test parameters can be set and details about the test carried out such as client details, test type, specimen type, user info...

Real Time Display The Test Data

Accommodate Various Testing Needs: software has a variety of pre-set programmed test cycles for compression, tensile and cyclical testing to meet a variety of testing standards.

Remote Control: via software, text execution, data analysis available through RS-232 port

Test Data Reports & Prints: test report printing options include direct to printer or excel file or graph export.

Structures

Specifications

| No | Description | Parameters | ||

| 1 | Model | HUD-B616 | ||

| 2 | Max. load | 300KN | 600KN | 1000KN |

| Load range | 6KN-300KN | 12KN-600KN | 20KN-1000KN | |

| Load accuracy | ±1% | |||

| Elongation resolution | 0.01mm | |||

| Piston stroke | 250mm | |||

| Max. piston stroke speed | 50mm/min | |||

| 3 | Elongation accuracy | ±1% | ||

| 4 | Max. Tensile space | 300mm(excluding piston stroke) | ||

| 5 | Max. Compression space | 250mm(excluding piston stroke) | ||

| 6 | Display mode | PC | ||

| 7 | Clamping mode | Hydraulic | ||

| 8 | Operation mode | Manual | ||

| 9 | Flat sample thickness | 0-15 mm | ||

| 10 | Clamping width | 70mm | 70mm | 125mm |

| 11 | Round sample diameter | Φ10-φ32 mm | Φ13-φ40 mm | Φ13-φ60 mm |

| 12 | Compression plate size | 170*170mm | 170*170mm | 204*204mm |

| 13 | Load frame dimensions | 900*750*2200mm | ||

| 14 | Oil source dimensions | 1200 x 550 x 1100mm | ||

Standards

Standards for Reference | |||||||||||||||||

Metal | |||||||||||||||||

Tensile tests at ambient temperature | Compression tests at ambient temperature | Shear Tests | Strand tensile tests | ||||||||||||||

ASTM E8M–09 | AS 1391 | ISO 15630-2 | ASTM C39 | EN12390-3 | ASTM E 143 | ASTM A 416 | |||||||||||

ASTM A370-07b | ASTM A 706/A, | 706M - 6a | ASTMC469 | DIN1048 | ASTM 496 | ||||||||||||

ASTM A185, A185M-07 | ASTM A48M-03 | EN 10002-1 | ISO 4506 | UNI6556 | BS 5896 | ||||||||||||

ASTM A615, A615M-09 | HB 5143 | EN 10080 | ISO6784 | ||||||||||||||

ASTM A82, A82M – 07 | ISO 15630-1 | JIS Z 2241 | |||||||||||||||

Metals and Construction Material | |||||||||||||||||

Bend Tests | |||||||||||||||||

ASTM A185/A185M – 07 | API 5L | ISO 7438 | |||||||||||||||

ASTM E190 | AWS B4.0 | ||||||||||||||||

Welded Fabric | |||||||||||||||||

Shear Tests | |||||||||||||||||

ASTM E8M – 09 | ASTM A82/ A82M | ISO 15630-2 | HB 5143 | ||||||||||||||

ASTM A370-07b | ASTM A 706/A | ISO 6394 | JIS Z 2241 | ||||||||||||||

ASTM A185/ A185M | AS 1391 706M - 06a | BS 18 | |||||||||||||||

ASTM A615/A615M-09 | ASTM A48M-03 | EN 10002-1 | |||||||||||||||

ASTM A82/ A82M – 07 | ISO 15630-1 | EN 10080– 07 | |||||||||||||||

Fasteners | |||||||||||||||||

Tensile tests for bolt | Nut load keeping tests | ||||||||||||||||

ASTM F606-07 | ISO 898-1 | ASTM E290 – 09 | ISO 7438 | ISO 15630-2 | JIS Z 2248 | ||||||||||||

AS 4291.1 | ASTM A370-07b | ISO 15630-1 | ISO 10065 | ||||||||||||||

Cement, Concrete and Rock | |||||||||||||||||

Flexural tests for cement | Compression tests for cement | Flexural tests for concrete | |||||||||||||||

ASTM C348 | ASTM C349 -08 | ASTM C 78 – 07 | |||||||||||||||

ASTM C1609 /, C1609M | ASTM C109, C109M – 08 | ISO 1920-4 | |||||||||||||||

ISO 679 | ISO 679 | ||||||||||||||||

BS EN 196-1 | BS EN 196-1 | ||||||||||||||||