Specifications

Item | Specification |

Load capacity | 5-2000kg (50N,100N,200N,500N,1kN,2kN,5kN,10kN,20kN,can be optional) |

Load cell brand | Imported brand load cell |

Motor | Panasonic servo motor |

Driver | 400w Panasonic driver |

Screw | High precision ball screw |

Control system | Computer control, Windows 7 or 10 system |

Test speed | 0.1-500mm/min(Adjustable) |

Stroke | 1200mm (Including clamp) |

Load resolution | 1/250,000 |

Load accuracy | ≤0.5% |

Unit | gf/kgf/N//kN/LBf/T |

Dimension | (L*W*H)880*505*1470mm |

Weight | Approx 183.9 KG |

Power | 1∮ AC 220V |

Features

DETAILS

Variety of Testing: integrates multiple independent testing functions such as tensile, deformation, peeling, tearing, and compression...

Testing Data Analysis: constant tensile stress, elastic modulus, stress and strain...

High Precision And Smooth Operation: double-pillar ball nut and screw drive

miniaturization and structural integration design

Intelligent Safe System: multi-level limit protection, overload protection, automatic high-speed return, and fault notification to ensure the user's operation safety.

Convenient Operations: embedded system and membrane key switch.

Data Transmission: the system is equipped with 4 usb ports and 2 network ports to facilitate data transmission and external access of the system.

Various Fixtures Can Be Chosen: equipped with more than 100 different sample fixtures for choose.

Universal Testing Materials: meet the test requirements of more than 1000 kinds of materials.

Customized Services: according to the different testing materials, huda also provides customized services to meet the testing needs of different customers.

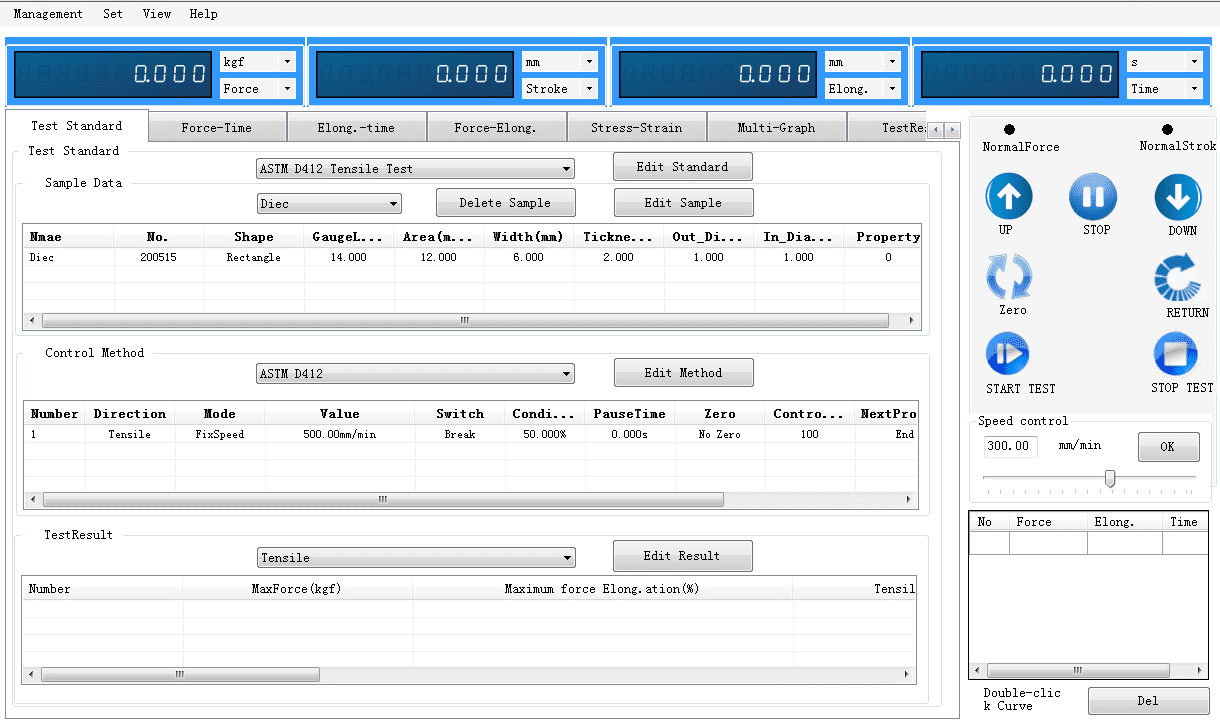

SOFTWARE

Statistical Analysis:group test curve overlay analysis, maximum, minimum, average, and standard deviation.

Multi-Curves Display And Real-Time Plot

Data Processing:file saving, setting loading, report printing and data comparing.

Various Testing: tensile test, compression test, bending test, peel test…

Various Test Actions: reciprocation, creep, hold tensile (compression), test pause, slip test, etc.

Software Protection: overload, over-displacement ,over-time protection.

Modularization of Specimen Setting

Modularization of Test Conditions

Applications

| Basic application | Extended application (Need special accessories or restructuring) | |||

| Tensile strength and deformation rate | Breaking force of ampoule | Film puncture force | Puncture force of lid of infusion bag with lid | Puncture/pulling force of soft rubber stopper |

| Breaking force | Combination cover opening force | ZD bottle cap tearing force | Oral fluid lid tearing force | Oral fluid cap puncture/pulling force |

| Heat seal strength | Pulling force of infusion bag cover inclined at 90 degrees | Pull-out force of lid for infusion bag with lid | 23 degree tilting cap pulling force | Piercing/pulling force with bottle cap and stopper |

| Tear resistance | 90 degree peel force of tape | Perfect bound pages tearing force | 90 degree water-based plaster peeling force | Adhesive tearing force |

| 180 degree peel | Adhesive strength test (soft) | Adhesive strength test (hard) | Peeling force of hose cap | Catheter and catheter joint disengagement force |

| 90 degree peel | Makeup brush bristles pulling force | Toothbrush bristles pulling force | Rope breaking force | Jelly cup and yogurt cup opening force |

| Fixed tensile test | Milk cup cup film peeling force | Extraction force of rubber plug | 45 degree peeling force of bottle film | Ziplock bag mouth pull force |

| Down test | Magnetic card core peeling force | 90 degree peeling force of magnetic card | Heat-sealing film tearing force | Protective film separation force |

| Puncture retention | Release paper separation force | Trouser tearing force | Unwinding force of tape | Pressure resistance of plastic bottles |

Standards

STANDARDS | |||

| Adhesives Tape/ Pressure Sensitive Tape | EN 1719: Loop Tack Test ASTM D3654: Shear Adhesion Test ASTM D3759: Tensile &Elongation Test FTM: 180&90 Degree Peel Test, Loop Tack EN 1939, ASTM D3330: 180&90 Degree Peel Test ISO 11339, ASTM D1876, ASTM F2256: T-type Peel Test | Adhesive | ASTM D903: Peel & Stripping Test ASTM D1002: Shear Strength (Adhesive for metal to metal) ISO 4587: Tensile lap-shear strength (Rigid-to-rigid bonded assemblies) |

| Film/Plastic Film | ASTM D882: Tensile Test ASTM F1306: Puncture Test ASTM D1938: Trouser Tear Test ASTM D2732: Thermal Shrinkage Test ASTM D1709, ISO 7765-1: Free-Falling Dart Method ASTM D1894: Static and Kinetic Coefficients of Friction ASTM D1424, ASTM D1922, ISO 1974: Elmendorf Tearing Strength Test | Plastic& Plastic Pipe | ISO 180: Izod Impact Test ISO 9966: Ring Stiffness Test ISO 179: Charpy Impact Test ISO 4892: Weathering Aging Test ASTM D3163: Plastic Lap-Shear Test ISO 4422, ISO 3127: Pipe Impact Test ASTM D4565, ISO 11357, EN 728: DSC/OIT ISO 75: Heat Deflection Temperature (HDT) ASTM D1598: Hydrostatic Pressure and Burst Test ISO 1133, ASTM D1238: Melt Flow Rate Test (MFR/MVR) ASTM D790, ISO 178, ISO 14125, ASTM D6272: Bend Test ISO 306, ASTM D1525: Vicat Softening Temperature (VST) ASTM D882, ASTM D 638, ISO 527, ASTM D1708: Tensile Test |

| Rubber | ASTM D412, ISO 37-2005, JIS K6251, DIN 53504-2009: Tensile Strength & Elongation Test ASTM D1149-07, ASTM D1171-99, ISO 7326, ISO1431-1, DIN 53509-1: Ozone Aging Test ASTM D624-00, ISO 34-1: Tearing strength Test ASTM D395-03, ISO 815-1: Compression Set Test ASTM D2240-05, ISO 7619-1, JIS K6253, ISO 868: Shore Hardness Type A/D ASTM D573, ASTM D865, ISO188 Method B, DIN 53508 High/ Low Temperature Test ISO 2781(Method A): Density Test ASTM D5289-95/ ISO6502: No-Rotor Rheometer/Curemeter ASTM D1646: Mooney Viscometer | Foam | ASTM D3574 Test E, ASTM D1623, ISO 1798: Tensile Test ASTM D3574 Test F, ISO 8067: Tear Test ASTM D3574 Test A: Density Test ASTM D3574 Test B1, ISO 2439: IFD Test ASTM D3574 Test H: Resilience (Ball Rebound) Test ASTM D3574 Test I3: Dynamic Fatigue Test by Constant Force |

| Metal | ASTM E8, EN 10002-1,ASTM A370: Tensile Test ASTM A370: Bend Test ASTM B-117, ISO 3768: Salt Spray Test ISO 6508: Rockwell Hardness Test ISO 6507: Vickers Hardness Test ISO 6506, ASTM E10-14: Brinell Hardness ASTM E23, ISO 148: Impact Test | ||