5 Major Advantages

From the source of materials to product packaging full testing

Production Process Full Testing

From the source of materials to product packaging full testing

- The performance and quality of the parts are checked at the first time of receiving the parts to ensure that the assembled parts meet the standards.

Incoming Inspection

- Semi-finished product testing, performance testing, finished product testing, to ensure that the strength of the product in each link online.

Production Inspection

- Factory equipment is tested and inspected in multiple directions to ensure that each device meets the factory standards.

Factory Testing

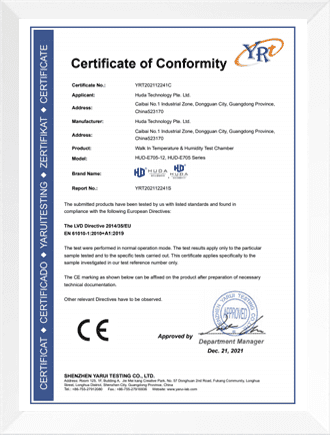

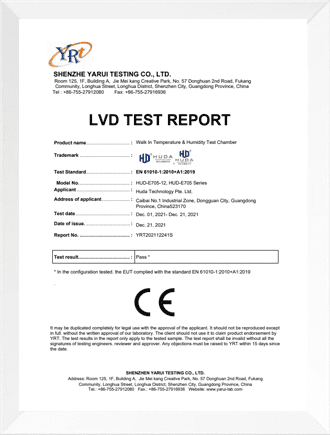

- The shipped equipment is tested by third-party inspection agencies and authoritative test reports are issued to ensure the accuracy of testing.

Third-Party Testing

Quality Inspection Process

10 testing process, to ensure quality from the source, exclusive logo, the production process is transparent and traceable

- 1Incoming Material Inspection

- 2Warehouse Acceptance

- 3Batching And Dispatching

- 4Workshop Assembly

- 5Semi-finished Product Inspection

- 10Fill In The Test Data And Test Report

- 9Actual Test On The Machine

- 8Finished Product Inspection

- 7Product Debugging

- 6Complete Assembly

- 1Incoming Material Inspection

- 2Warehouse Acceptance

- 3Batching And Dispatching

- 4Workshop Assembly

- 5Semi-finished Product Inspection

- 6Complete Assembly

- 7Product Debugging

- 8Finished Product Inspection

- 9Actual Test On The Machine

- 10Fill In The Test Data And Test Report

Product Testing Site

Take you into the real test site, good quality can be seen

Good Quality Certified By Authority

Full product inspection, exclusive logo, transparent and traceable production process, responsible for product quality