Description

Description

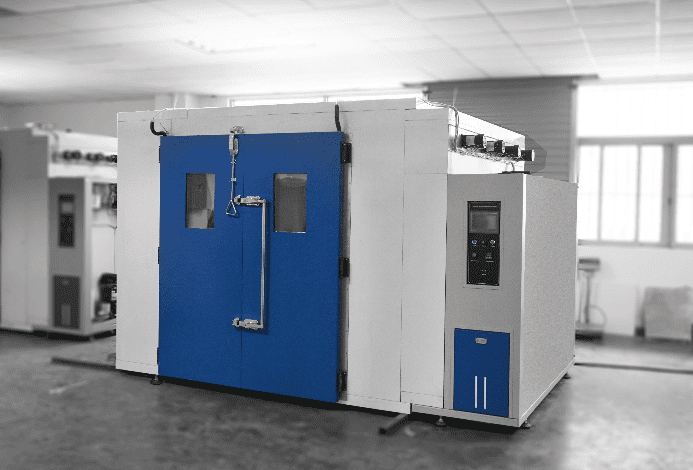

Solar Panel Test Chamber testing solar panels, grid-tied photovoltaic inverters, or photovoltaic cells and modules.

Solar Panel Test Chambers are designed to test Solar Panels as per IEC test standards in order to prove their performance, reliability, durability and service life. There are three test methods that are performed; Thermal Cycle Test, Humidity Freeze Test and Damp Heat Test. Details of these tests are below:

Thermal Cycle Test: Thermal cycle test is performed according to IEC 61215:2005 standard to test ability of PV module to withstand effects of temperature stress. This test is performed between temperature 85°C and -40°C with fast changing rate. Number of cycles is run 50 or 200 times.

Humidity Freeze Test: Humidity freeze test is performed to determine ability of PV modules withstand against high temperature and humidity conditions followed by sub-zero temperature. In this this 10 cycles are run between 85°C with 85% relative humidity and negative temperature -40°C.

Damp Heat Test: Damp heat test is performed to test effects of long exposure of humidity penetration and high temperature. In this test is performed by applying 85°C ±2°C temperature with relative humidity of 85% for uninterrupted cycle of 1000 hours.

In order to perform above mentioned tests, we make Environmental Test Chambers or Climatic Test Chambers that can perform these tests effectively. As solar panels come in different sizes and dimensions; therefore, solar panel environmental chambers are also made according their sizes. Whatever the panel size, small, medium or large; we can design the test chamber that meets your requirement under your price budget. Our Solar panel environmental test chambers are made of imported components and fabricated with stainless steel sheets using CNC and laser machines. Digital touch control panel enables you to save temperature, humidity settings with controllable rate and dwell times. Data recording facility is inbuilt. Imported branded refrigeration system lets you experience trouble free negative temperature for long hours. Special stainless steel rack system is provided to hold PV modules inside chamber. We supply our solar panel test chambers all over worldwide at factory price with complete installation, commissioning and after sales service.

Contact Haida for your custom solar panel testing needs.

Specifications

Model | HUD-E705-S |

Inner dimension | 4m³, 8m³, 10m³, 15m³, 20m³, 25m³, 30m³, 40m³ (sizes can be customized) |

Temperature range | -20/-40/-70~150℃ (optional) |

Sample limit | This test equipment prohibits the test of flammable, explosive, and volatile substance samples; the test of storing corrosive substance samples, the test of storing organisms, the test and storage of storing strong electromagnetic emission source samples |

Power supply & its conditions | 3¢380VAC±10%, 50Hz Three-phase four-wire system N + protective grounding Allowable voltage fluctuation range: 10% Allowable frequency fluctuation range: (50±0.5) Hz The grounding resistance of the protective earth wire is less than 4Ω The user is required to configure an air or power switch with corresponding capacity for the equipment at the installation site, and this switch must independently control the use of the equipment |

Performance | |

Functional requirements | (Air) Indoor space cooling, heating, humidification, and dehumidification; According to the temperature and humidity setting, the indoor space reaches the set temperature and humidity |

Test environment conditions | The ambient temperature is +25°C, relative humidity ≤85%, and the value measured under the condition that there is no sample in the test box. |

Temperature & Humidity Range | |

Humidity range | Humidity range: 20~98%HR |

Control precision | Temperature resolution: 0.01°C Humidity resolution: 0.1%RH Temperature deviation: ±1.5°C Humidity deviation: ±2%RH Temperature uniformity: ≤2°C Humidity uniformity: ≤3%RH Temperature fluctuation: ±0.5°C Humidity fluctuation: ± 2%RH |

Temperature rise and fall rate (no load) | +25℃→+80℃≤35 min +25℃→-40℃ ≤60 min |

Note: The above performance indicators are the values measured under the condition that the ambient temperature is +25°C, the water temperature is 28°C, the relative humidity is ≤85%, and there is no sample. | |

Chamber | |

Structure | Combined assembly board, detachable structure, convenient for on-site installation. |

Exterior materials | Color steel plate φ=0.8mm |

Interior materials | Stainless steel plate SUS304φ=0.8mm |

Library body thickness | 100mm insulation material is rigid polyurethane foam |

Floor load | Reinforced bottom plate, can load 600kg/㎡ (evenly distributed load) |

Material of the door | Same as warehouse board |

Thickness of the door | 100mm insulation material is rigid polyurethane foam |

Door | Double door, effective headroom size W1500*H2200mm, |

Door lock | Japanese door lock, strong door hinge, with anti-deadlock device |

Observation window | Two observation windows: Two W300*H450mm conductive film explosion-proof and anti-fog tempered glass observation windows are set on the door, |

Test hole | 1 test hole, size: Φ100mm, position to be determined by the customer |

Air conditioning channel | Built-in air room, circulating air duct and stainless steel circulating fan, through the top back leaf window and diffuser, the wind blows out from the top evenly, and distributes the tempered temperature in the tempering room to the test space, so as to achieve the purpose of uniform temperature control |

Control panel | South Korea imported TEMI2700 LCD touch type programmable controller Lighting switch, main power switch, RS-232 communication interface |

Machinery room | Refrigeration unit, exhaust fan, drainage device, water vapor outlet |

Power distribution control cabinet | Main power circuit breaker, controller, switchboard, cooling fan, over-temperature protector |

Heating system | Use scale heat dissipation heating tube P.I.D to control heating to achieve temperature balance |

Cooling system | Heat exchanger: water-cooled condenser |

Mode of transport | The machine room is transported as a whole, and the warehouse body is packaged and transported |

Electrical Control System | |

Controller | Imported controller to control temperature and humidity separately South Korea SAMWON, color touch screen control TEMI2700 |

Screen display function | Temperature and humidity setting (SV) actual (PV) value is directly displayed Can display the execution program number, segment number, remaining time and cycle number, running time display Program editing and graphic curve display With a separate program editing screen, each page can enter 4 segments of temperature, humidity, and time Fixed-point or program action status display Language switch can switch Chinese/English 7.5 True color display screen |

Program capacity and control function | The amount of programs that can be used: 120 groups at most, 1 program can be combined from 1 to 100 stages Usable memory capacity: 1200 SEGMENTS Commands can be executed repeatedly: each command can be up to 999 times The program slope setting can be set by the time axis Each segment between programs can be set up to 99 hours and 99 minutes, and the minimum is one minute, which can be set for connection use With editing, clearing, inserting and other functions With 4 sets of time signal output control (can control the ON/OFF action of the test object) With 9 groups of PID parameter settings Jump and hold function during program execution The screen can be adjusted for backlight, and the backlight time can be set Screen display protection function can be set timed or manually closed Program copy, COPY, connection function, edit experiment title and other program editing functions PID automatic calculation and FUZZY control function With power-off program memory, it will automatically start and continue to execute the program after power is restored With scheduled start-up and shutdown function With date and time adjustment function Button and screen lock (LOCK) function With standby view function With network connection function |

RS-232 | Can be connected to the computer to display the curve and obtain data Can be used as a monitoring and remote control system Can do synchronous control of multiple machines |

Communication interface | Used to store test data and test curves, the standard storage capacity is 2G, which can be expanded to 4G |

SD memory card | Chinese/English interface, touch input |

Setting method | Program method / fixed value method |

Operation mode | The upper and lower limits of the maximum temperature range 5℃ |

Display resolution | Temperature: 0.01℃; Humidity: 0.1%; Time: 1min; |

Power-off memory function | The power-off recovery mode can be set as: hot start/cold start/stop |

Schedule boot function | The power-on time can be set at will, and the machine will run automatically when the power is turned on |

Temperature measuring body | PT100 platinum resistance |

Curve record function | With battery-protected RAM, it can save the set value, sampling value and sampling time of the device; the maximum recording time is 60 days (when the sampling period is 1.5min) |

Software use environment | IBM PC compatible machine, CPU above PⅡ, memory above 128M, Simplified Chinese Windows2000 or Simplified Chinese WindowsXP operating system |

Internet connection | It can be connected to the Ethernet network through professional software, remote control and remote assistance can be done through the network, and test data can be collected through the network, and multiple machines can be controlled at the same time |

Predetermined area | Temperature: Adjust according to the temperature working range of the equipment (upper limit +5℃, lower limit -5℃) |

Input | Platinum resistance/DC 1~5V input |

Ancillary function(standard configuration) | Fault alarm and reason, processing prompt function Power-off protection function Upper and lower limit temperature protection function |

Cooling System | |

Cooling method | In order to ensure the cooling rate and minimum temperature requirements of the laboratory, this laboratory adopts a set of binary compound refrigeration system. The cascade system includes a high-temperature refrigeration cycle and a low-temperature refrigeration cycle. The heat exchange is realized by an evaporative condenser. |

Refrigeration Compressors | Imported low-temperature compressor |

Condenser | Water-cooled heat exchanger |

Evaporator | Finned tube heat exchanger |

Evaporative condenser | Stainless steel brazed plate heat exchanger |

Throttling device | Thermal expansion valve, capillary tube |

Refrigerator control method | The PLC (Programmable Logic Controller) of the control system automatically adjusts the operating conditions of the refrigerator according to the test conditions Compressor return air cooling circuit Energy pressure regulating valve |

Refrigerant | Using environmentally friendly refrigerant R404A+R23 with an ozone depletion index of 0 |

Refrigeration system characteristics | The pipelines of the whole system are tested for leak detection by venting and pressurizing 22kg. The heating and cooling systems are completely independent. Equipped with the company's professional technical characteristics, it can prevent the damage of the high-temperature and high-pressure airflow co-current cooling machine. All operating procedures of the refrigeration system are completely controlled by the microcomputer controller. There is a drip pan at the bottom of the compressor, which can collect the condensation water produced by frost. The compressor has its own PTC temperature sensor, when the compressor is over-temperature, it can realize over-temperature protection. The compressor has its own oil pressure protector to realize compressor oil pressure protection. The high and low pressure protection device monitors the pressure of the refrigerant during the working process of the equipment. Once the pressure of the refrigerant is higher than the limit pressure of the system or lower than the minimum pressure set by the system, an alarm will be issued immediately and the power supply will be cut off until the fault is eliminated . The refrigeration system all uses imported brand accessories, which are reliable in quality and ensure the stability of the system. |

Humidification & Dehumidification System | |

Replenishment method | Three-stage filter filtration, water pump lifts automatic water supply, circulating filtration and recovery |

Humidification and dehumidification method | Adopt external humidification method, special dehumidification compressor starts dehumidification, P.I.D controls the humidification amount to reach the required humidity |

Safety Protection System | |

Cooling System | Compressor overheating, overcurrent, overpressure protection, etc. |

Test box | Limit over temperature, fan, motor overheating relay |

Humidification system | Dry heating of humidification heat pipe, abnormal water supply, abnormal drainage, abnormal water shortage |

Power supply | Leakage protection, overload and short circuit protection |