Specifications

Item | Specification |

Load capacity | 5~200kg (50N,100N,200N,250N,500N,1kN,2kN,can be optional) |

Load cell brand | Imported brand load cell |

Motor | 400w Panasonic servo motor |

Actuator | 400w servo actuator |

Screw | High precision Ball screw |

Control system | PC with windows 7 or 10 system |

Test speed | 0.01-500mm/min (adjustable) |

Vertical test space | 900mm (including clamp) |

Load resolution | 1/250,000 |

Load accuracy | ≤0.5% |

Force reading | gf/kgf/N//kN/LBf/T |

External dimension | (L*W*H)515*520*1250mm |

Weight | About 68KG |

Power | 1∮ AC 220V |

Detailed Content

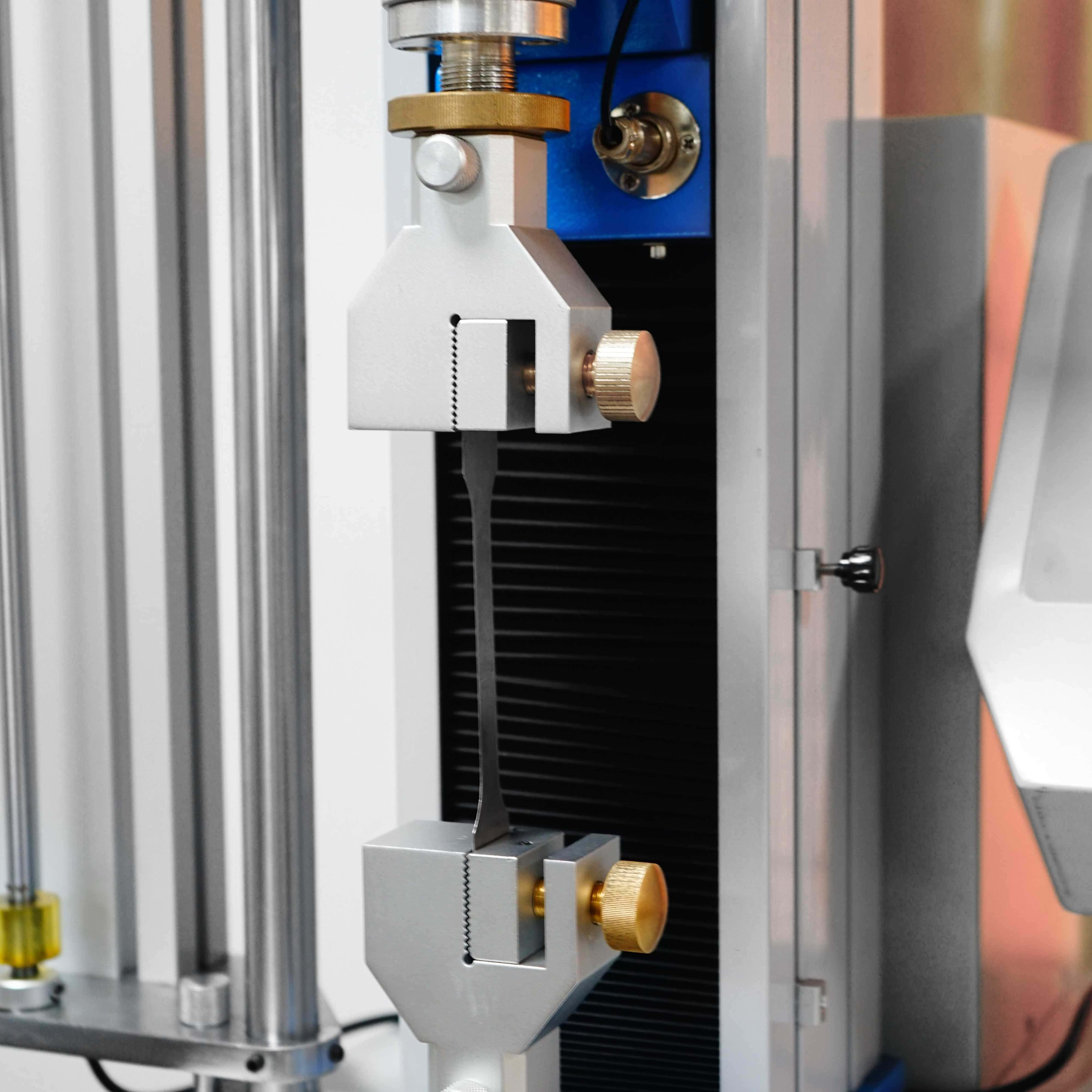

STRUCTURE FEATURES

Ten processes to address diversity needsEquipment integrates ten professional independent test procedures, such as tensile, peeling, tearing, heat sealing, fixed extension tensile, lower pressure, puncture retention force, etc., and provides users with a variety of test items.

Support rubber plug puncture, ampoule breaking force and other compression test, test speed can be set freely

Intelligent design of limit protection, overload protection, automatic return, etc. To ensure safe OPERATION

ADVANCED TESTING ORGANIZATION ACCURACY

Equipped with a force-value testing system for world-renowned brands, providing better force-value accuracy than level 0.5, better repeatability and more flexible testing

Equipped with a world-renowned brand servo operating system, with precision ball screw multi-axis positioning technology, to provide better than 0.5 level displacement accuracy, poleless speed regulation, easy to use, more stable operation.

HIGH-END EMBEDDED COMPUTER PLATFORM SAFE AND EASY TO USE

Support group test data comparison analysis, with multi-unit conversion function

the system are convenient for external access and data transmission

Applications

Basic application | Extended application (Need special accessories or restructuring) | |||

Tensile strength and deformation rate | Breaking force of ampoule | Film puncture force | Puncture force of lid of infusion bag with lid | Puncture/pulling force of soft rubber stopper |

Breaking force | Combination cover opening force | ZD bottle cap tearing force | Oral fluid lid tearing force | Oral fluid cap puncture/pulling force |

Heat seal strength | Pulling force of infusion bag cover inclined at 90 degrees | Pull-out force of lid for infusion bag with lid | 23 degree tilting cap pulling force | Piercing/pulling force with bottle cap and stopper |

Tear resistance | 90 degree peel force of tape | Perfect bound pages tearing force | 90 degree water-based plaster peeling force | Adhesive tearing force |

180 degree peel | Adhesive strength test (soft) | Adhesive strength test (hard) | Peeling force of hose cap | Catheter and catheter joint disengagement force |

90 degree peel | Makeup brush bristles pulling force | Toothbrush bristles pulling force | Rope breaking force | Jelly cup and yogurt cup opening force |

Fixed tensile test | Milk cup cup film peeling force | Extraction force of rubber plug | 45 degree peeling force of bottle film | Ziplock bag mouth pull force |

Down test | Magnetic card core peeling force | 90 degree peeling force of magnetic card | Heat-sealing film tearing force | Protective film separation force |

Puncture retention | Release paper separation force | Trouser tearing force | Unwinding force of tape | Pressure resistance of plastic bottles |

Standards

Adhesives Tape/Pressure Sensitive Tape

Ø EN 1719: Loop Tack Test

Ø ASTM D3654: Shear Adhesion Test

Ø ASTM D3759: Tensile &Elongation Test

Ø FTM: 180&90 Degree Peel Test, Loop Tack

Ø EN 1939, ASTM D3330: 180&90 Degree Peel Test

Ø ISO 11339, ASTM D1876, ASTM F2256: T-type Peel Test

Adhesive

Ø ASTM D903: Peel & Stripping Test

Ø ASTM D1002: Shear Strength (Adhesive for metal to metal)

Ø ISO 4587: Tensile lap-shear strength (Rigid-to-rigid bonded assemblies)

Film/Plastic Film

Ø ASTM D882: Tensile Test

Ø ASTM F1306: Puncture Test

Ø ASTM D1938: Trouser Tear Test

Ø ASTM D2732: Thermal Shrinkage Test

Ø ASTM D1709, ISO 7765-1: Free-Falling Dart Method

Ø ASTM D1894: Static and Kinetic Coefficients of Friction

Ø ASTM D1424, ASTM D1922, ISO 1974: Elmendorf Tearing Strength Test

Plastic& Plastic Pipe

Ø ISO 180: Izod Impact Test

Ø ISO 9966: Ring Stiffness Test

Ø ISO 179: Charpy Impact Test

Ø ISO 4892: Weathering Aging Test

Ø ASTM D3163: Plastic Lap-Shear Test

Ø ISO 4422, ISO 3127: Pipe Impact Test

Ø ASTM D4565, ISO 11357, EN 728: DSC/OIT

Ø ISO 75: Heat Deflection Temperature (HDT)

Ø ASTM D1598: Hydrostatic Pressure and Burst Test

Ø ISO 1133, ASTM D1238: Melt Flow Rate Test (MFR/MVR)

Ø ASTM D790, ISO 178, ISO 14125, ASTM D6272: Bend Test

Ø ISO 306, ASTM D1525: Vicat Softening Temperature (VST)

Ø ASTM D882, ASTM D 638, ISO 527, ASTM D1708: Tensile Test

Rubber

Ø ASTM D412, ISO 37-2005, JIS K6251, DIN 53504-2009: Tensile Strength & Elongation Test

Ø ASTM D1149-07, ASTM D1171-99, ISO 7326, ISO1431-1, DIN 53509-1: Ozone Aging Test

Ø ASTM D624-00, ISO 34-1: Tearing strength Test

Ø ASTM D395-03, ISO 815-1: Compression Set Test

Ø ASTM D2240-05, ISO 7619-1, JIS K6253, ISO 868: Shore Hardness Type A/D

Ø ASTM D573, ASTM D865, ISO188 Method B, DIN 53508 High/ Low Temperature Test

Ø ISO 2781(Method A): Density Test

Ø ASTM D5289-95/ ISO6502: No-Rotor Rheometer/Curemeter

Ø ASTM D1646: Mooney Viscometer

Foam

Ø ASTM D3574 Test E, ASTM D1623, ISO 1798: Tensile Test

Ø ASTM D3574 Test F, ISO 8067: Tear Test

Ø ASTM D3574 Test A: Density Test

Ø ASTM D3574 Test B1, ISO 2439: IFD Test

Ø ASTM D3574 Test H: Resilience (Ball Rebound) Test

Ø ASTM D3574 Test I3: Dynamic Fatigue Test by Constant Force

Metal

Ø ASTM E8, EN 10002-1,ASTM A370: Tensile Test

Ø ASTM A370: Bend Test

Ø ASTM B-117, ISO 3768: Salt Spray Test

Ø ISO 6508: Rockwell Hardness Test

Ø ISO 6507: Vickers Hardness Test

Ø ISO 6506, ASTM E10-14: Brinell Hardness

Ø ASTM E23, ISO 148: Impact Test

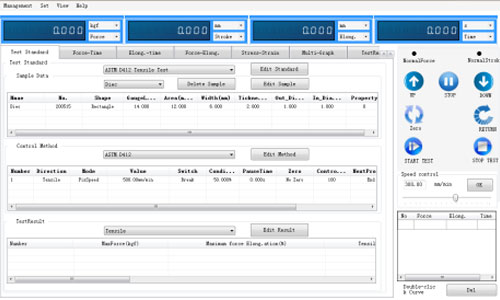

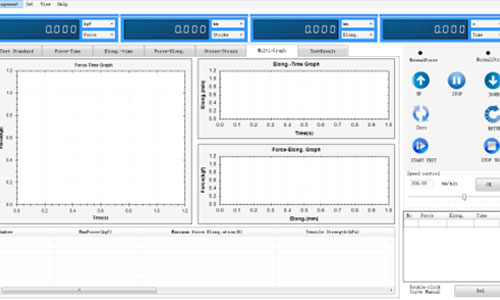

Huda Software

Curves display picture

User setting page