Lithium Battery Safety Testing

With the wide application of lithium batteries in the fields of communication and electronic appliances, our requirements for the safety performance, reliability performance and cycle life of the battery are getting higher and higher.

In order to ensure the safety of lithium batteries, relevant organizations have formulated various safety testing standards for lithium batteries.

4 Kinds of Battery Safety Testing

Testing standards generally divide the safety testing into the following 4 categories:

1. Electrical test: over-charge, over-discharge, external short circuit, forced discharge, etc.

2. Mechanical test: extrusion, acupuncture, shock, vibration, drop, etc.

3. Thermal test: high and low temperature cycle, combustion, microwave heating, etc.

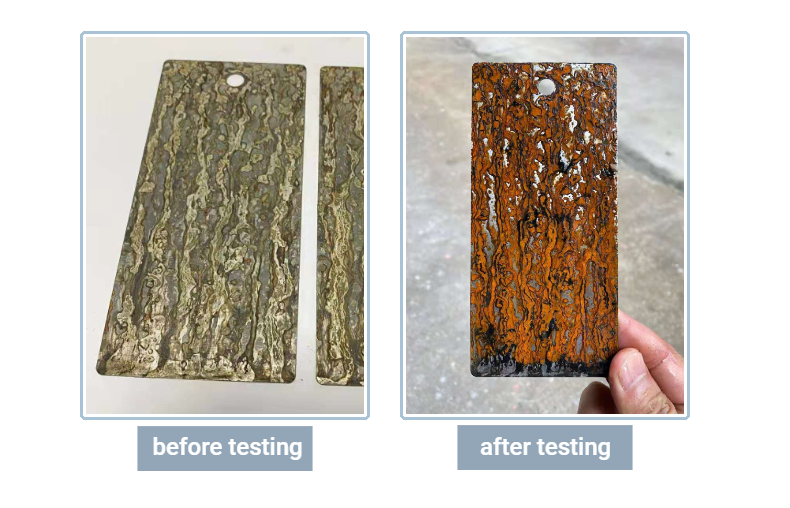

4. Environmental simulation test: high altitude and low pressure simulation, salt spray test, etc.

Battery Test Machines for Special Testing

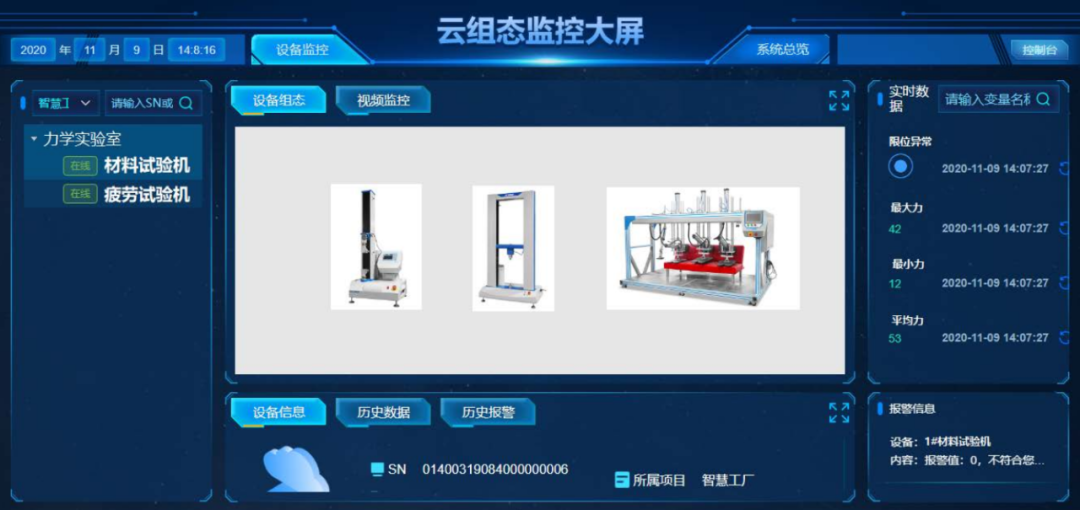

In order to ensure the safety performance of the battery, check the unqualified battery and avoid the occurrence of battery safety accidents,different safety testings need different testing equipment.

As a result, more and more lithium battery manufacturers have increased demand for battery safety testing equipment. External short-circuit testing requires a battery short-circuit test chamber. According to different standards, the short-circuit test chamber is divided into normal temperature short circuit and temperature-controlled short circuit. Extrusion, acupuncture, impact, vibration, drop, combustion, high-altitude and low-pressure tests all require professional battery testing machines.

Huda provide professional lab battery test solutions for customers. Welcome to consultant!