Single-axis Vibration Test Systems

Single-axis vibration test systems are used to simulate real-world vibrations that products may experience during transportation, operation, or other environmental conditions. These systems typically consist of a vibration table or platform onto which the test specimen is mounted, along with one or more actuators or shakers that produce controlled vibrations along a single axis.

Here's how they generally work:

Test Specimen Mounting: The item or product to be tested is securely mounted onto the vibration table or platform. This ensures that it experiences the vibrations accurately and without damage.

Actuators or Shakers: These are the components responsible for generating vibrations. They are typically electromechanical devices capable of producing controlled oscillations along a single axis. The amplitude, frequency, and waveform of the vibrations can be adjusted as per the testing requirements.

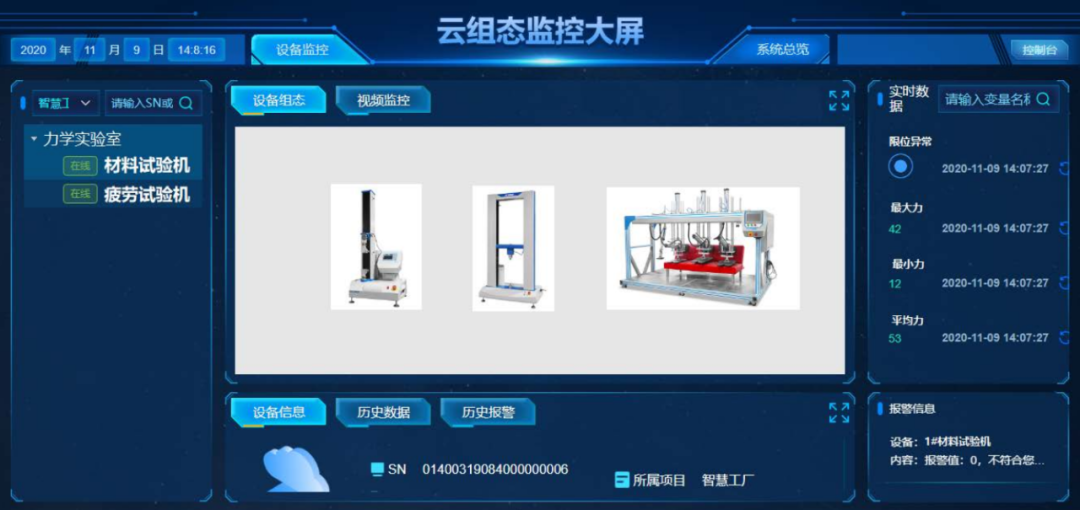

Control System: A control system governs the operation of the vibration test system. It allows the user to set parameters such as vibration amplitude, frequency, duration, and waveform. Advanced control systems may also incorporate feedback mechanisms to ensure precise control and monitoring of the vibrations.

Data Acquisition: During the test, various sensors may be used to measure and record data such as vibration levels, frequency response, and structural integrity of the test specimen. This data is crucial for evaluating the performance and durability of the product under vibration conditions.

Applications of single-axis vibration test systems include:

Product Reliability Testing: Ensuring that products can withstand vibrations encountered during transportation, handling, or operation.

Quality Control: Verifying the quality and durability of components and assemblies subjected to vibration.

Research and Development: Studying the effects of vibration on materials, structures, and systems to improve product design and performance.

Regulatory Compliance: Meeting industry standards and regulations that require products to undergo vibration testing to ensure safety and reliability.

These systems are widely used in industries such as automotive, aerospace, electronics, and consumer goods to assess the robustness and reliability of products before they are brought to market.