Universal tensile machine common problem solution

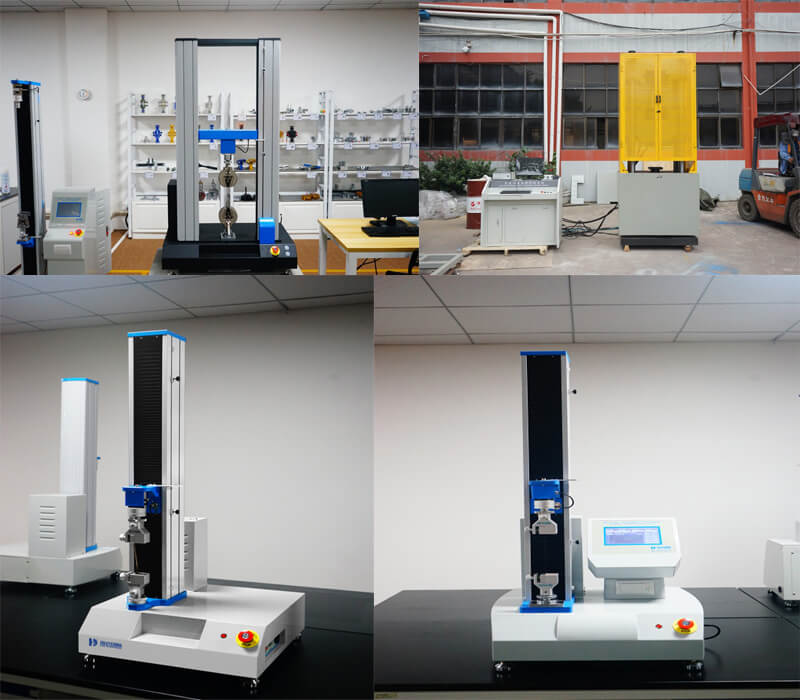

The universal tensile machine is an essential piece of equipment in materials testing labs that measures the tensile strength of various materials. However, like any other machine, it can experience common problems that can affect its accuracy and performance. In this article, we will explore the solutions to some of these common problems.

Inaccurate Readings: One of the most common problems with the universal tensile machine is inaccurate readings. This can be caused by several factors, including incorrect calibration, worn-out grips, or a malfunctioning load cell. To solve this problem, the machine should be regularly calibrated using the appropriate calibration standards. The grips should also be inspected and replaced if worn out. Finally, the load cell should be checked for proper functioning and replaced if necessary.

Slipping Specimens: Another common problem is slipping specimens. This occurs when the specimen slips out of the grips during the testing process, resulting in inaccurate readings. To prevent this, it is important to ensure that the grips are properly tightened to hold the specimen securely in place. Additionally, using grips with serrated surfaces can help increase friction and prevent slipping.

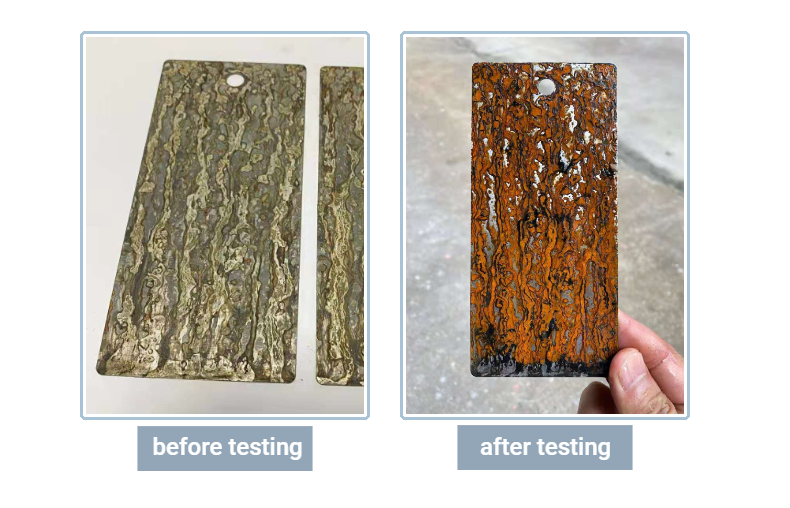

Specimen Damage: Sometimes, specimens can be damaged during testing, leading to inaccurate results. This can happen if the specimen is not properly prepared, or if the grips are too tight. To prevent this, it is important to properly prepare the specimen, including cutting it to the correct size and shape, and using the appropriate grips. It is also important to ensure that the grips are not too tight, as this can cause damage to the specimen.

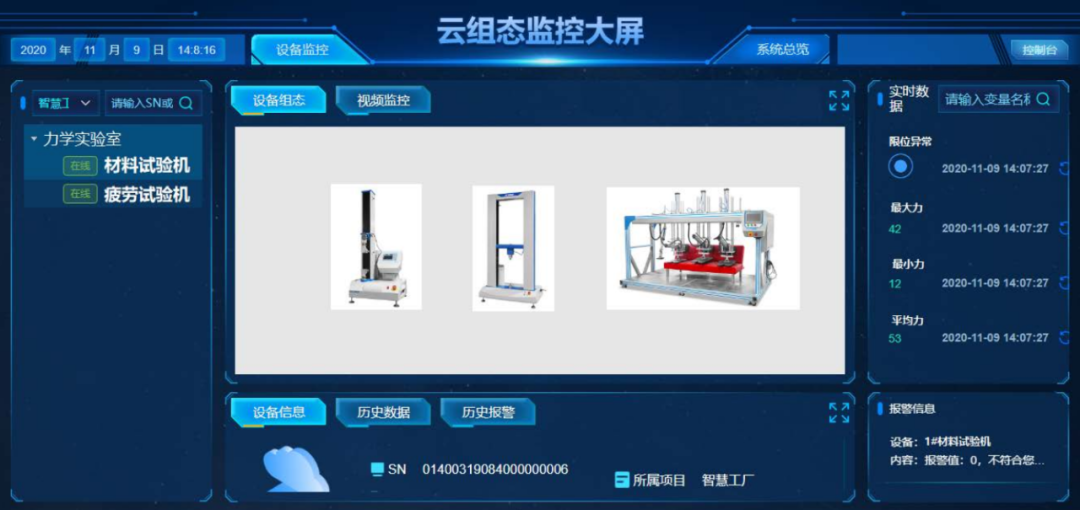

Software Malfunction: Another common problem with the universal tensile machine is software malfunction. This can be caused by a variety of factors, including corrupted software, outdated drivers, or hardware failure. To solve this problem, it is important to ensure that the software is up-to-date and that all drivers are properly installed. Additionally, the hardware should be checked for any signs of damage or malfunction.

Overloading: Overloading the machine can cause damage to the load cell and other components, leading to inaccurate readings and reduced lifespan of the machine. To prevent overloading, it is important to use the appropriate load cell for the specimen being tested and to follow the manufacturer's guidelines for maximum loads.

Maintenance Issues: Regular maintenance is important for ensuring the optimal performance and accuracy of the universal tensile machine. Neglecting to perform regular maintenance, such as lubrication, cleaning, and inspection, can lead to a variety of problems, including inaccurate readings and reduced lifespan of the machine. To prevent these problems, it is important to follow the manufacturer's guidelines for maintenance and to perform regular inspections and maintenance tasks.

In conclusion, the universal tensile machine is a valuable piece of equipment in materials testing labs. However, like any other machine, it can experience common problems that can affect its accuracy and performance. By following the guidelines outlined in this article, including regular maintenance, proper specimen preparation, and the use of appropriate grips and load cells, it is possible to prevent and solve many of these problems and ensure accurate and reliable results from the machine.