Details

TEST PROCESS

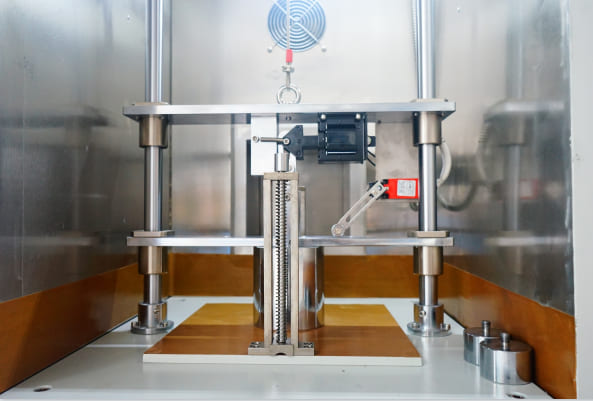

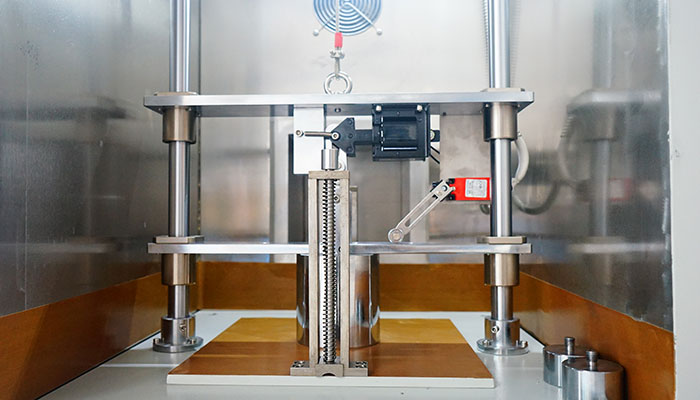

The battery of the test sample shall be placed on a flat surface, and a rod with a diameter of 15.8 ± 0.2 mm (5/8 inch) shall be placed on the center of the sample in a crisscross pattern. 9.1kg or 10kg weight dropped from a certain height (610mm or 1000mm) onto the sample.

When a cylindrical or square battery is subjected to an impact test, its longitudinal axis should be parallel to the plane and perpendicular to the longitudinal axis of the steel column. The longest axis of the square battery is perpendicular to the steel column, and the largest surface is perpendicular to the impact direction. Each battery only accepts one impact test. If the battery does not catch fire, it is qualified if it does not explode.

TEST STANDARD

UL1642: 2012, UL 2054 "Lithium Battery Standard"

UN38.3 "Lithium Batteries and Battery Pack Testing Standard Regulations"

IEC62133GB/T 18287-2013 "General Specification for Lithium Ion Batteries for Cellular Phones Heavy Object Impact Test"

GB 31241-2014 "Safety requirements for lithium-ion batteries and battery packs for portable electronic products"

GB-31241-2014 "Safety Requirements for Lithium Ion Batteries and Battery Packs for Portable Electronic Products"

QB/T2502 "General Specification for Lithium Ion Batteries"

Specifications

| Model | HUD-H206 |

| 1. Weight | 9.1kg and 10kg; |

2. Impact height | 0-1000mm (can be set); |

3. Height display | LED meter display; |

4. Displacement accuracy | ≤±5mm; |

5. Impact method | free fall; |

6. Control mode | PLC touch screen control; |

7. Impact floor material | No. 45 steel, thickness 30 password; |

8. Metal rod | 15.8±0.2mm (5/8 inch) steel rod; |

9. Internal material | SUS#304 stainless steel plate, thickness 1.2mm; Teflon melt adhesive tape is applied to 1/3 of the place, high temperature resistance, corrosion resistance, insulation and easy to clean. |

10. External material | cold-rolled sheet baking varnish treatment, thickness 1.5mm; |

11. Pressure relief door size | 200x200mm; |

12. Smoke exhaust pipe | diameter φ100mm, located at the back of the box; |

13. Box door | a single door opens to the left, and an explosion-proof chain is installed on the side of the box door; |

14. The maximum size of the battery tested | 200x200x200mm (width x depth x height); |

15. Inner box size | 490x520x1430mm (width x depth x height); |

16. Dimensions | 700x1000x1720mm (width x depth x height, including door lock); |

17. Impact method | lift the falling ball to a certain height and release it, and the falling ball falls freely in the vertical direction, without tilting or shaking; |

18. Power supply | 1∮, AC220V, 3A |

19. Power supply power | 700W |

20. Weight (approximately) | about 270kg |