Specifications

Item | Specification |

Internal Dimension (W*D*H) | 600*600*800mm |

External Dimension (W*D*H) | 1250*1150*1850mm |

Inner chamber material | SUS 304 # Stainless Steel, Anti-rust, easy to clean |

Outer chamber material | Stainless steel |

Chamber Temperature | Room temperature+10℃~70℃ |

Temperature Uniformity | ±3℃ |

Temperature accuracy | ±0.1℃ |

Blank panel temperature | 65±3℃ |

Humidity Range | Light :20%~60%RH, Dark:30%~98%RH |

Humidity fluctuation | +2,-3%RH |

Irradiated intensity | 300-400NM,40~60W/m2 |

Xenon lamp power | 6.5KW water-cooled xenon lamp x 1pc |

Turntable speed and diameter | 1~7r/min, diameter 400mm |

Lamp life | About 1200h |

Control system | PLC controller, touch screen |

Distance from specimen to arc center | 250~300mm, Effective exposure area 3760cm2 |

Standard sample size | 75mm×150mm Thickness<20mm |

Filter | Daylight filter |

Lighting cycle time | 0~999H, M, S continuously adjustable |

Door seal | Silicone rubber seal |

Temperature sensor | PT100 high precision temperature sensor |

Air circulation system | Stainless steel centrifugal rotor vane to improve the uniformity of temperature and humidity |

Cooling ventilator | Automatic controlled by temperature controller, and inner chamber cooled by refrigerating system |

Cooling ventilator | France Tecumseh compressor |

Power | Three phase, AC380V, 50Hz |

Cooling method | Water ( with one chiller) |

Test standard | ISO105-B02:2014 |

Safety Protection | Over heat protection for fan, Over load protection for cooling system, Over pressure protection for cooling system, Over temperature protection, Over heat and over flow protection for water pump, Leakage protection, Water shortage protection, Auto stop after failure warning |

Features

DETAILS

1.Ventilation system: Automatic controlled by temperature controller, and inner chamber cooled by refrigerating system.

2.Back panel thermometer: adopt wired transmission technology, which highly improve the control accuracy.

3.Temperature sensor: PT100 platinum resistance thermocouple.

4.Equip with intelligent temperature and humidity controller, with PID adjustment and rapid self-turning. It can set several parameters to do cyclic test, directly digital temperature display for easy reading.

5.Multiple protective devices: Over temperature protection, water leakage alarm, over pressure of compressor, electricity leakage protection, alarm and auto power offer protection. In order to protect Xenon light, the light will turn off automatically once open the door.

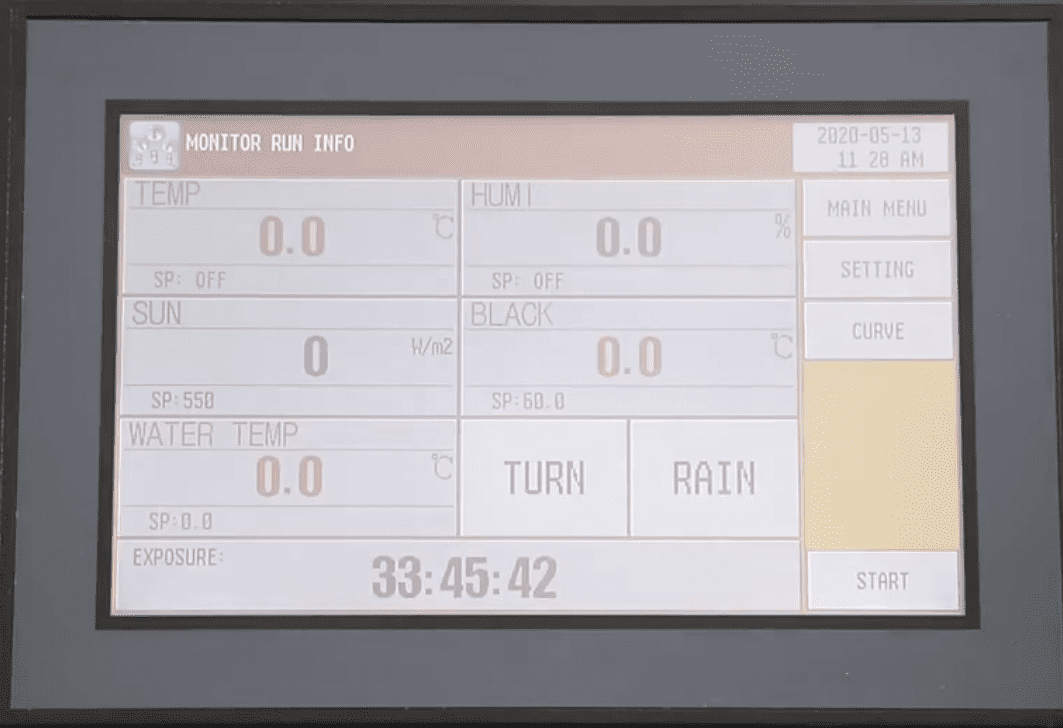

CONTROLLER

PID programmable color touch screen controller, network connection computer.

Preset program into the controller based on user testing requirements.

Can edit 120 programs 100 segments.

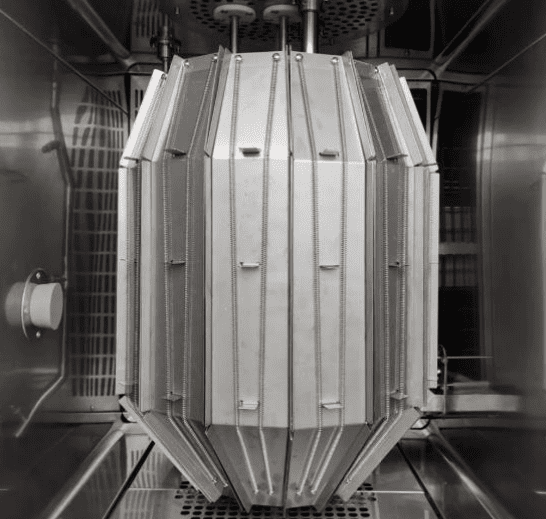

ROTATING SPECIMEN HOLDER

Inside there is a rotating specimen holder, which rotates around the xenon lamp,so that the irradiance received by the specimen is relatively uniform during the test.

Total can mount 42 pieces of specimen.

RADIOMETER

UV Irradiance Radiometer is available for xenon test chamber.

The radiometer is a photoelectric sensor with fast response, reliable performance and high accuracy.