Unleashing the Power of Thermal Cycle Test Chambers Evaluating Product Durability with Precision

In the realm of product design and development, ensuring durability and reliability is paramount. The ability to withstand extreme temperature variations is a vital characteristic that separates exceptional products from the rest. Thus, it becomes imperative for manufacturers to invest in cutting-edge testing methodologies to evaluate the thermal mechanical properties of their products effectively. Step forward, the thermal cycle test chamber – a remarkable invention that harnesses the power of rapid temperature changes to assess and enhance the durability of diverse specimens.

Unveiling the Functionality of Thermal Cycle Test Chambers

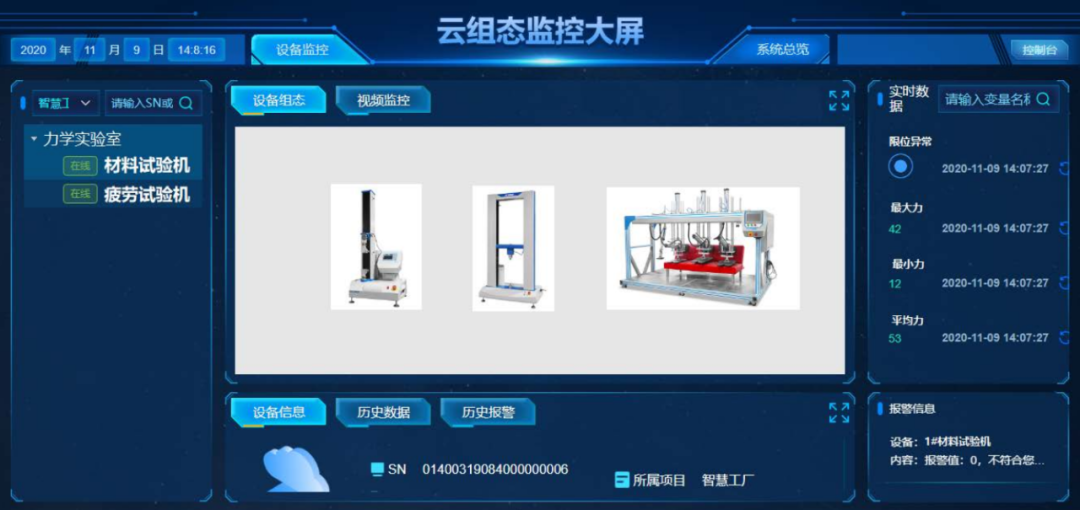

A thermal cycle test chamber is specifically designed to meet the demands of specimens requiring quick and rigorous temperature fluctuations. Through a series of meticulously designed climatic conditions, including holding, cooling-off, heating-up, and drying tests, these chambers meticulously evaluate a product's thermal mechanical properties. By subjecting specimens to such strenuous conditions, manufacturers can identify weaknesses, study their effects, and make informed design or material improvements.

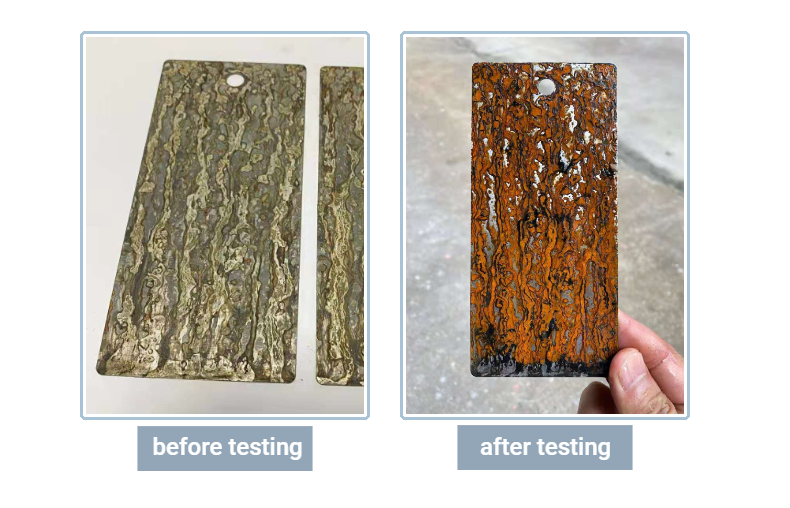

Analyzing the Failure Points

The ultimate objective of any product testing endeavor is to identify potential failure points before they manifest themselves during real-world usage. Thermal cycle test chambers allow manufacturers to simulate the harshest environments that a product might encounter, enabling them to evaluate its thermal resilience under various temperatures. Such evaluations significantly contribute to the longevity of a product, ensuring that it can withstand the test of time, extreme climates, and demanding work environments.

Unleashing the Benefits of Thermal Cycle Test Chambers

1. Enhanced Product Reliability: Thermal cycle test chambers provide invaluable insights by simulating harsh conditions, enabling manufacturers to make necessary design or material improvements to increase the reliability and durability of their products. This optimization process ensures that products not only meet but exceed customer expectations.

2. Saves Time and Money: By thoroughly assessing a product's thermal mechanical properties early in the development process, manufacturers can rectify any potential flaws before mass production. This proactive approach saves both time and money, preventing costly recalls, repairs, or replacements in the future.

3. Improved Customer Satisfaction: By subjecting products to rigorous testing and ensuring their ability to withstand demanding environments, manufacturers can confidently offer products that meet and surpass customer expectations. Such reliability lends itself to increased customer satisfaction, loyalty, and positive brand image.

4. Research and Development: Thermal cycle test chambers serve as an indispensable tool within research and development departments. They facilitate the development of innovative products that can thrive in extreme conditions, pushing the boundaries of what is possible in numerous industries.

In a world where quality, durability, and reliability matter, thermal cycle test chambers have emerged as an essential asset for manufacturers. These chambers provide an efficient and effective means of evaluating a product's thermal mechanical properties, empowering manufacturers to make informed improvements that lead to enhanced durability. By embracing the power of thermal cycle test chambers, manufacturers can unlock a world of opportunities, delivering exceptional products that far surpass customer expectations. So, are you ready to put your products to the thermal endurance test?