Specifications

| Model | HUD-E710-2 |

| Internal dimension | (W*D*H)1000*1000*1000mm |

External dimension | (W*D*H)1300*1100*1700mm |

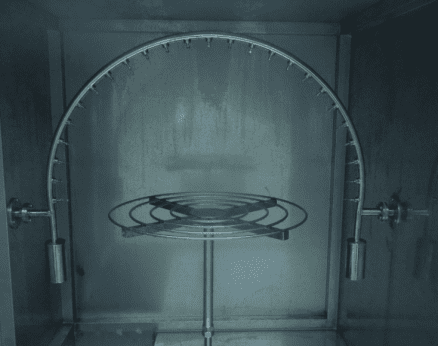

Oscillating tube | Radius 400mm |

Oscillating angle | IPX3: spray ±60° from vertical line to each side, total 120° IPX4: spray ±180° from vertical line to each side, total 360° |

Oscillating speed | IPX3: 2*120° for 4s IPX4: 2*360° for 12s |

Spray nozzle | Diameter: 0.4mm, removable Ensure the water sprays in a line and without tolerance |

Distance between two nozzles | 50mm |

Turntable diameter | 500mm |

Turntable rotation speed | 1-3 cycles/min |

Water flow of each nozzle | 0.07 L/min +5% |

Test duration | 1~999h999min, adjustable |

Pressure gauge | 80-150Kpa |

Distance from nozzle to specimen surface | 200mm |

Chamber material | Stainless steel, with observation window |

Safety protection device | Short circuit protection, grounding protection, water shortage protection, audible and visual alarm |

Power supply source | 1-phase, 220V±10%, 50Hz (can be appointed) |

Features

DETAILS

Chamber material: SUS stainless steel plate

Stainless steel swing pipe: the radius is R400mm, and 24±1 nozzle is evenly distributed every 50mm on the entire circumference. The pendulum tube drive device uses a motor to adjust the pendulum speed of the pendulum tube. It is realized by mechanical transmission such as motor driven reducer, eccentric wheel mechanism, gear rack and pinion. Adjust the desired angle by means of an eccentric mechanism.

Stainless steel table: with rotation speed regulation function.

Tempered glass door: can directly observe the working state of the rain.

Detachable special nozzle: made of copper, specially processed, the spray direction of each nozzle can be adjusted (within 45 ° range), and finally the adjusted nozzle can be adjusted to a plane, facing the same center point. (This is one of our know-how).

Stainless steel water supply tank: equipped with water pump, water quality filter, inlet float valve, drain valve.

Drainage hole: at the bottom of the chamber to be able to discharge quickly, no water accumulation.

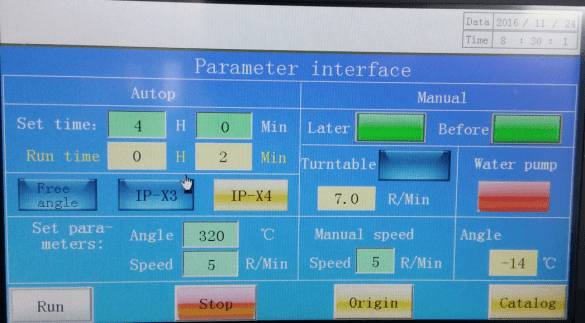

CONTROL SYSTEM

High-precision LCD program controller to complete the time and sequence control of the entire system;

Imported frequency converter to control the speed effectively ensures that the test runs according to the standard;

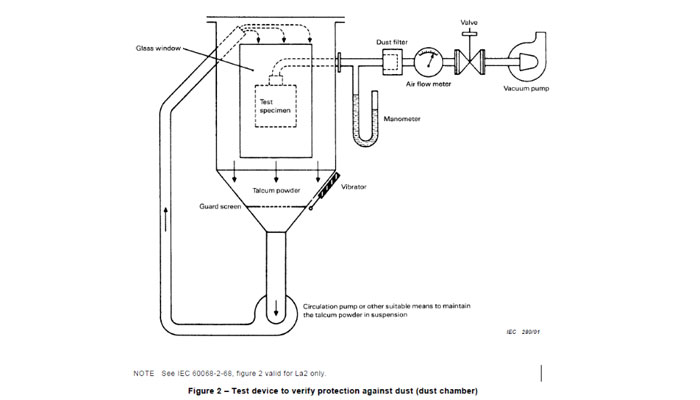

DESIGN AS PER IEC60529

IP series

| IP SERIES | ||

IPX-1 | Protected against falling water | Equivalent to 3-5mm rainfall per minute for a duration of 10 minutes. Unit is placed in its normal operating position. |

IPX-2 | Protected against falling water | when tilted up to 15 degrees - Same as IPX-1 but unit is tested in 4 fixed positions - tilted 15 degrees in each direction from normal operating position. |

IPX-3 | Protected against spraying water | Water spraying up to 60 degrees from vertical at 10 liters/min at a pressure of 80-100kN/m2 for 5 min. |

IPX-4 | Protected against splashing water | Same as IPX-3 but water is sprayed at all angles. |

IPX-5 | Protected against water jets | Water projected at all angles through a 6.3mm nozzle at a flow rate of 12.5 liters/min at a pressure of 30kN/m2 for 3 minutes from a distance of 3 meters. |

IPX-6 | Protected against heavy seas | Water projected at all angles through a 12.5mm nozzle at a flow rate of 100 liters/min at a pressure of 100kN/m2 for 3 minutes from a distance of 3 meters. |

IPX-7 | Protected against water immersion | Immersion for 30 minutes at a depth of 1 meter. |

IPX-8 | Protected against water submersion | The equipment is suitable for continual submersion in water under conditions which are identified by the manufacturer. |

IPX-9 | Protection against high-pressure water splashes | The water pressure should be 8–10 MPa (80–100 bar) at distance of 0.10–0.15 meters.The water temperature should be 80 °C. |